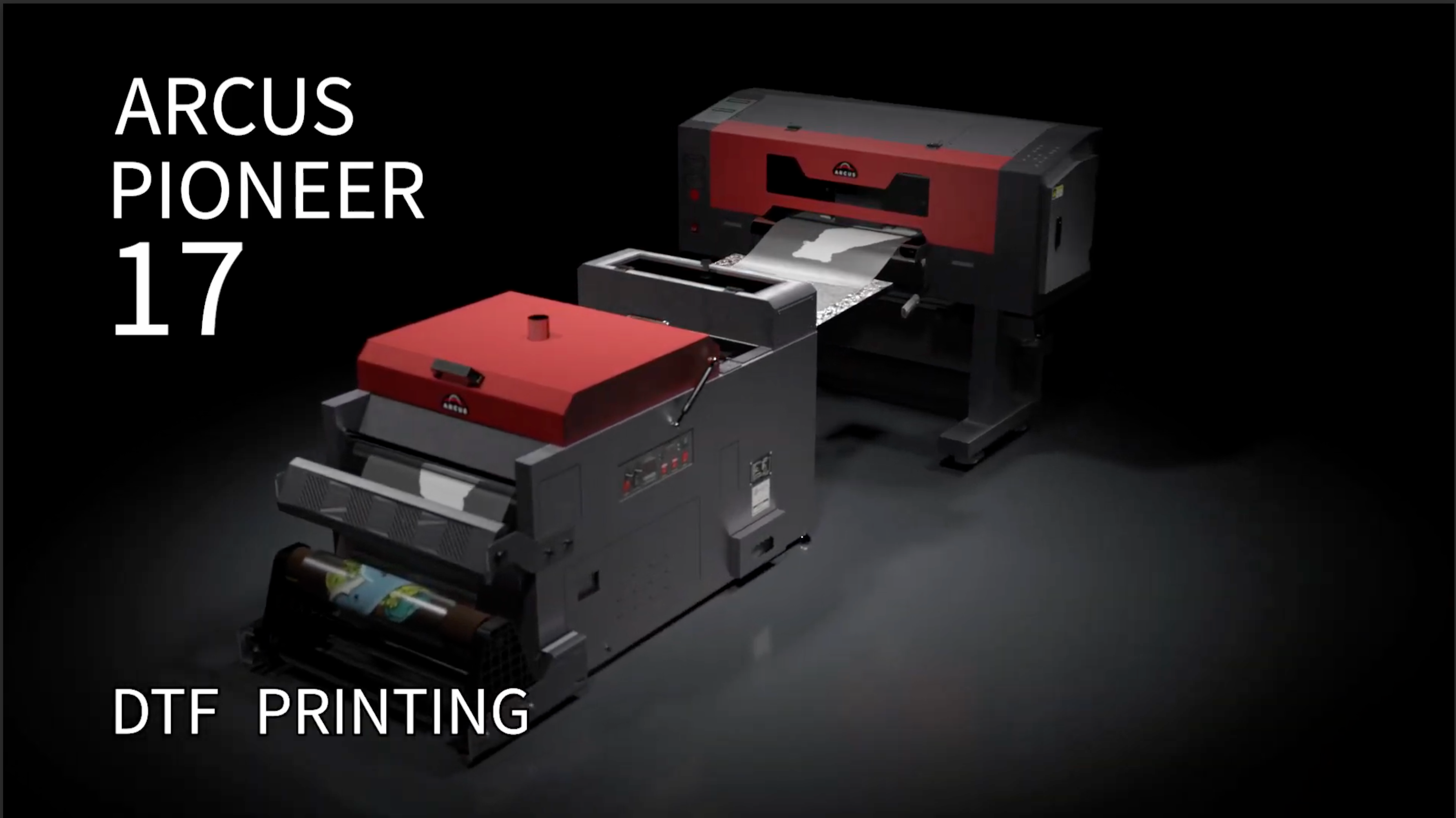

Introducing the

Pioneer 17 2-Head DTF Printer

The All-in-One Solution for High-Performance DTF Production

The Pioneer 17 2 Head Direct-to Film (DTF) Printer System is engineered for decorators who want industrial-level performance in a compact, easy-to-place machine.

Powered by the industrial EPSON I3200 printhead and capable of handling up to 17" film, the Pioneer 17 2-Head DTF printer delivers faster output, bigger prints, and sharper detail with every run. This printer’s innovative powder retaining system and 1-liter ink tanks keep your shop’s production running longer with fewer interruptions.

Built with Arcus Printers’ durable, space-saving design, a slim profile that fits through standard doorways, and an all-in-one shaker/dryer for automated curing, the Pioneer 17 2-Head is the production-ready solution that takes you from setup to high-performance output without compromise.

High-Speed, High-Resolution, Precision Printing

UP TO

108 sqft/hr

SPEED

UP TO

1800

DPI RESOLUTION

Key Features

Industrial EPSON I3200 Printhead

The dual I3200 printheads deliver high-resolution output with precise #PL droplet sizes and a recessed nozzle plate that resists damage, ensuring faster, sharper, and more reliable printing than competitor models.

High-Speed, Wide-Format Printing

Print up to 108 sqft/hr at production speeds with resolutions up to 720 x 1800 dpi. The 17” film width maximizes nesting capacity and allows for larger, more profitable designs per run.

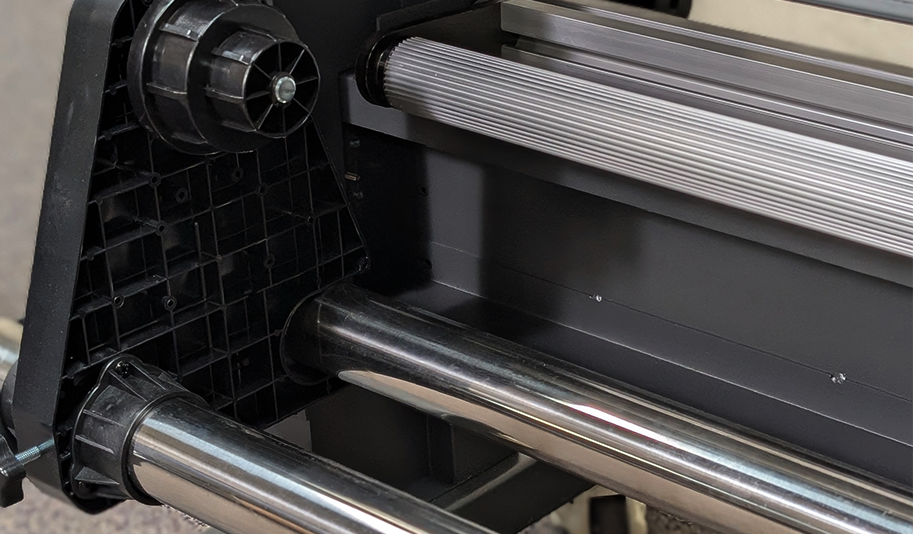

Innovative Powder Retaining System

A first-of-its-kind retaining rod/axle consistently coats and transfers with adhesive powder while extending unattended operation. Less frequent refills mean fewer workflow interruptions and smoother long-run output.

Large-Capacity Ink Tanks

With onboard 1-liter ink reservoirs, the Pioneer 17 2-Head keeps moving longer between refills, reducing downtime and consumable costs.

Compact, Space-Saving Design

Slim enough to fit through standard doorways and powered by a standard 110v outlet, the Pioneer 17 installs easily in any size shop without costly electrical upgrades or extra floor space.

All-in-One Shaker/Dryer

Unlike entry-level setups that require manual powdering and curing, the integrated shaker/dryer automates the process: applying powder, curing transfers, and rewinding finished rolls for true production-level efficiency.

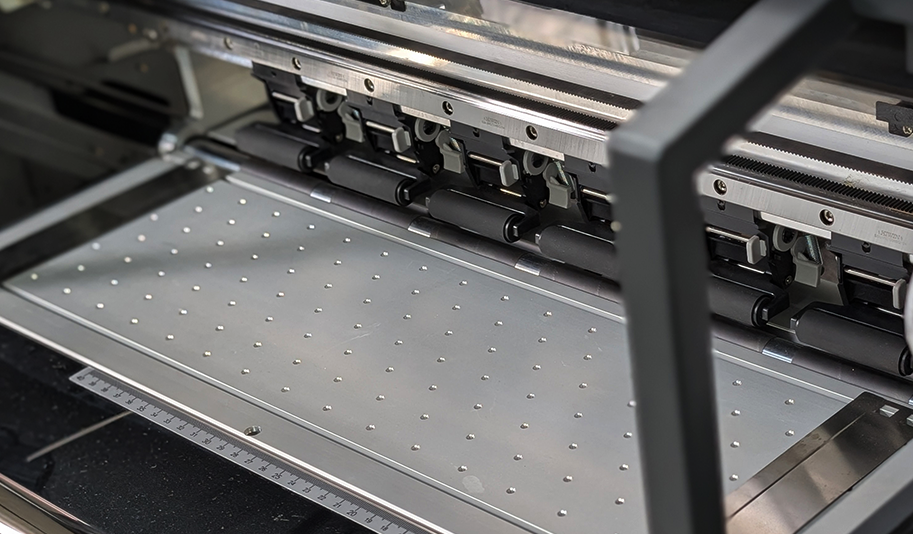

Precision Media Control

Features like the dancer bar system, powered unwind/rewind, and an anti-static platen design keep media feeding smoothly from start to finish, reducing head strikes, misfeeds, and alignment issues.

Reliability and Uptime Features

Reliability and

Uptime Features

Industrial-Grade Servo Motors:

The Pioneer 17’s heavy-duty motors deliver longer life, greater accuracy, and consistent output, even in high-volume shops.

White Ink Stirring and Recirculation:

This system prevents the titanium dioxide particles in the white pigment from settling, so the white ink moves smoothly through the print head for consistent white coverage.

Wet Mode Preservation:

When you activate the printer’s wet mode from the included Arcus Link Software, you’ll ensure that your nozzles don’t dry or clog when you’re not using the printer or transporting it.

Automatic/Manual Cleaning and Capping:

Programmable head cleaning with auto-lift capping keeps printheads performing at their best, while manual controls give you backup and flexibility for long-term reliability.

Manual Maintenance Station Adjustment:

Easily adjust the maintenance station height to cap printheads during a power outage or access them quickly for service and upkeep.

Easy Access Panels:

Get fast access to critical areas of your printer setup for repair and regular maintenance.

SPECIFICATIONS

General

Printer Type:

Direct-to-Film (DTF) Printer with Integrated Shaker/Dryer

Model:

Pioneer 17 2-Head

Print Head Type:

Epson I3200

Number of Print Heads:

2

Ink Type:

DTF Pigment Ink

Ink Colors:

C / M / Y / K / White

Ink Technology:

Piezoelectric Variable Dot Inkjet

Ink Capacity:

1L onboard bulk tanks

Printing Area:

DTF transfer film up to 17" wide

Max Media Width:

17"

Printable Width:

16.5"

Printing

Supported Printing Modes:

- Color + White layering (variable pass configurations)

Printing Speed:

- Production Mode: Up to 108 sqft/hr

- High-Quality Mode: 75 sqft/hr

- Metric Equivalent: ~5 sqm/hr at 720 × 1800 dpi (Production)

Resolution:

Up to 720 × 1800 dpi (variable 720/1800/2400 dpi, 1–8 passes)

Supported Media

Film Media:

DTF transfer film up to 17" wide

Media Type:

DTF Film

File Format Support:

TIFF, JPEG, PNG, PDF, EPS

Color Configuration:

CMYK + White

Build & Hardware

Industrial Guide Rails:

HWIN imported precision rails for accuracy

Print Platform:

Precision media feed system with dancer bar, powered unwind/rewind, and anti-static platen design

Motion System

X-Axis:

180W Leadshine servo motor

Y-Axis:

Industrial-grade stepper motor

Film Control

Rubber Roller Film Advance:

Yes

Motorized Unwind:

Yes

Tension/Dancer Bar for Unwind:

Yes

Ink System

White Ink Recirculation:

Yes (prevents pigment settling for smooth flow)

Ink Level & Low Ink Warning System:

Yes (bulk + subtanks)

Curing & Vacuum System

Pre-Powder Heated Platen:

Removes moisture, cures ink before powder application

Powder Application & Curing:

All-in-one shaker/dryer with adjustable curing bed speed and temperature controls

Powder Catch Tray:

Yes

Powder Retention System While on Film:

Yes

Heating Elements:

High-quality IR heaters within the shaker

Air Management

Air Fume Extraction:

External

Air Filtration Type:

Filter

Complimentary Air Purifier/Fume Extractor Included

Software & Compatibility

RIP Software:

Fiery RIP software for Arcus DTF Printers V12

Color Control:

ICC color management with adjustable curves/density

Machine Control Software:

ArcusLink for remote monitoring, diagnostics, and wet mode preservation

Dimensions & Power

Equipment Size:

50.4″ L × 40.2″ W × 25.6″ H (128 × 102 × 65 cm)

Packaging Size:

63″ L × 29.9″ W × 28″ H (160 × 76 × 71 cm)

Weight:

242.5 lbs.

Shaker Size:

50.4″ L × 26.8″ W × 30.7″ H (128 × 68 × 78 cm)

Shaker Crated Size:

65.4″ L × 30.7″ W × 39.8″ H (166 × 78 × 101 cm)

Shaker Weight:

242.5 lbs.

Shaker Crated Weight:

265 lbs.

System Weight (Printer + Shaker):

485 lbs.

Operating Voltage:

110V, single-phase (standard outlet)

Power Consumption:

3.4 kW total (Printer: 1.5 kW / 13.6A, Shaker: 1.9 kW / 17.3A)

Operating Environment

Temperature:

68–86°F

Humidity:

40%–60%

Safety Features

Carriage Collision Stop Sensor:

Protects print heads